WASK Teeset

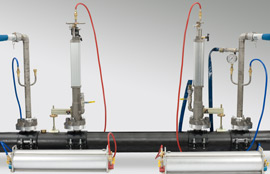

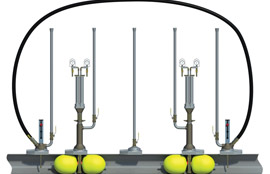

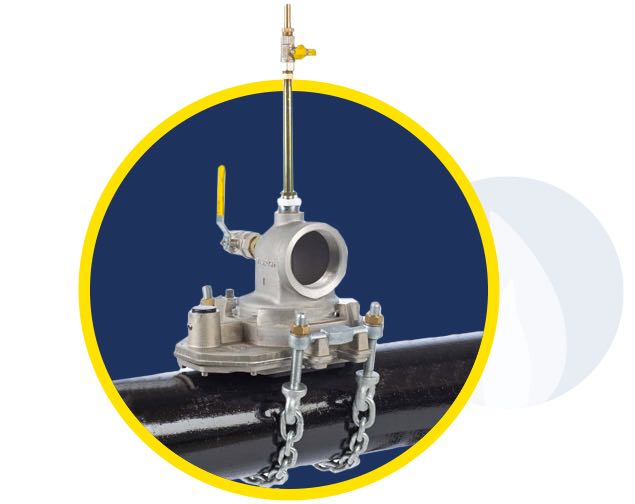

The Teeset drilling and tapping machine together with the bagging and By-pass system provide a robust and safe means of maintaining and extending live gas mains.

The machine will also fit ancillaries such as plugs, bushes, side entry tees, standpipes, bag pipes, main spraying heads etc, under no gas conditions.