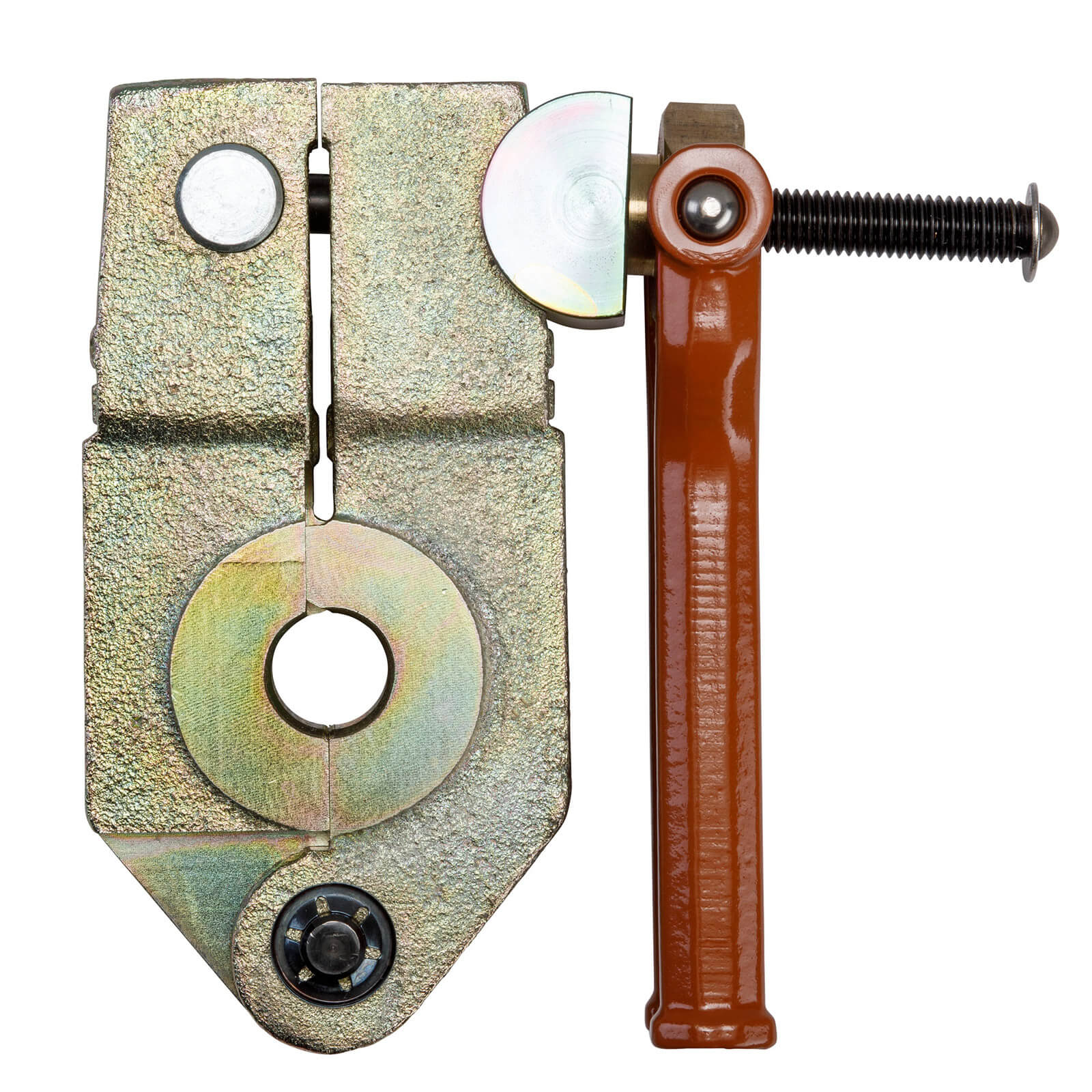

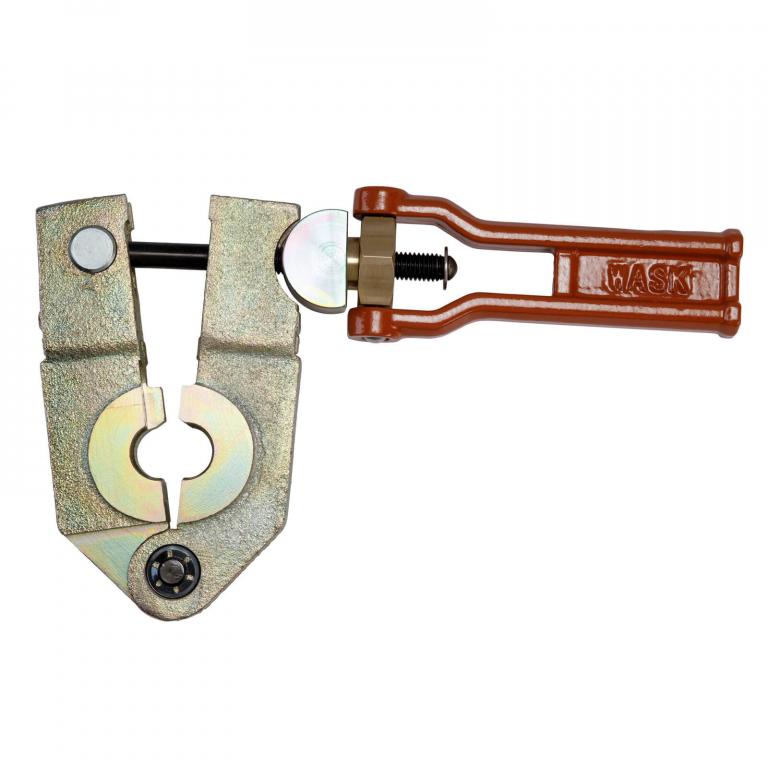

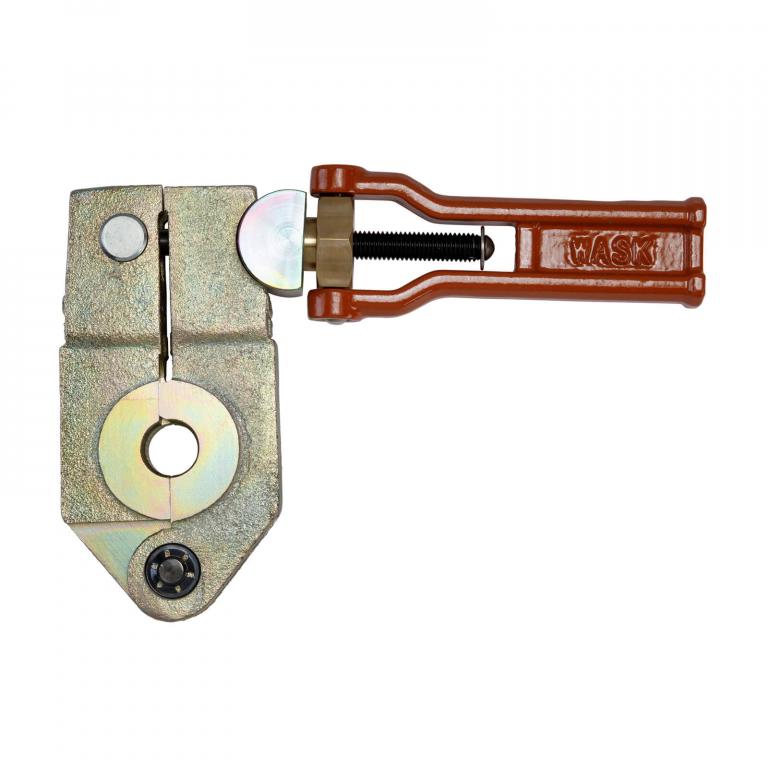

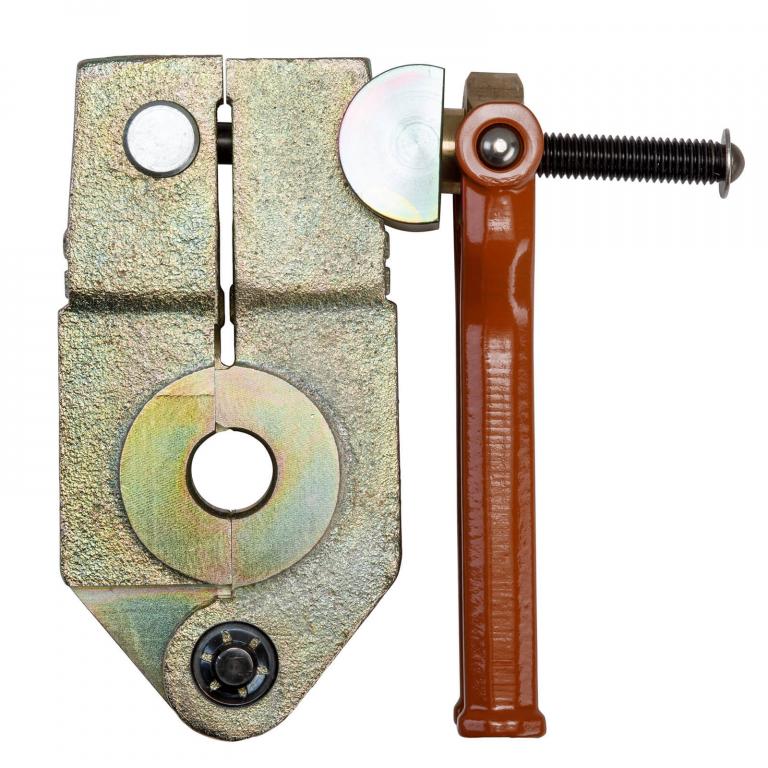

Crimp Tool

WASK has updated the range of CRIMP tools. Based on the operators that are using our tool every day, we have identified how the WASK CRIMP tools can be better and easier to use.

We have redesigned the handle to make the tool more comfortable to use when working in tight spaces. By allowing, the handle to move over the screw you can now work more comfortably.

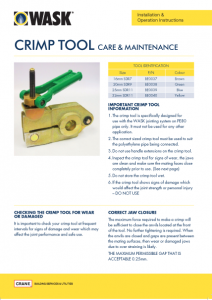

We are sending the new tool care & maintenance sheet so you can have further information about it.