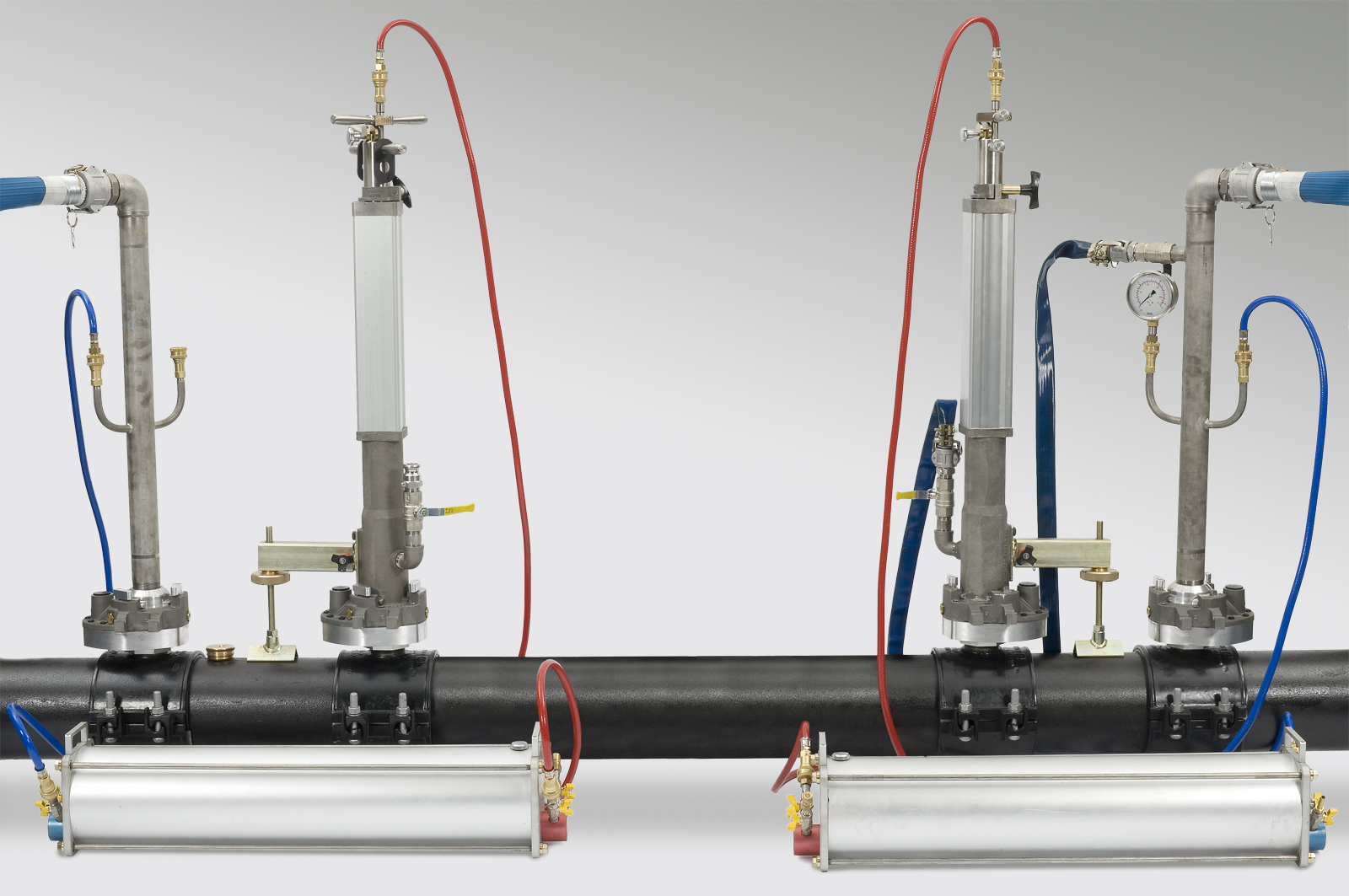

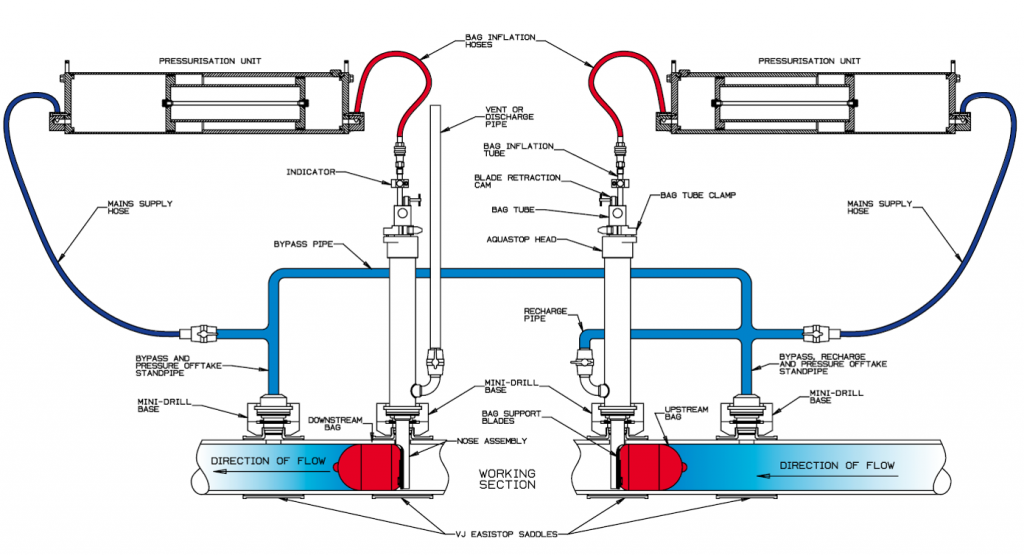

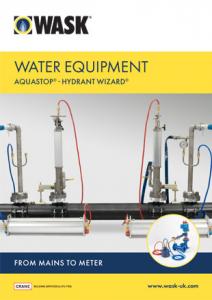

Aquastop

An easy to use, self-contained and powered solution to line stop a water main

WASK Aquastop equipment is designed to stop water flow in 3” (80mm) to 8“ (200mm) nominal bore pipes with minimal disruption to the main system.